Are you wondering about what really keeps critical pharma manufacturing spaces free of dangerous microorganisms? Understanding the VHP (Vaporized Hydrogen Peroxide) Cycle of Isolators is essential—especially for those targeting careers or businesses in pharmaceutical manufacturing, quality assurance, GMP (Good Manufacturing Practice) compliance, or sterilization.

With global regulations and patient safety standards getting stricter every year, knowing how isolator decontamination works can be a major advantage for pharmaceutical professionals and companies.

Contents

Why You Need to Know About the VHP Cycle of Isolators

Whether you manage a pharmaceutical manufacturing plant or strive for top-tier quality assurance in drug production, contamination control is non-negotiable. One failed sterilization procedure can risk patient safety, regulatory compliance, product recalls, and even company reputation. That’s why the Vaporized Hydrogen Peroxide (VHP) cycle is a critical focus for industry leaders, regulatory auditors, and anyone aiming for excellence in pharma careers.

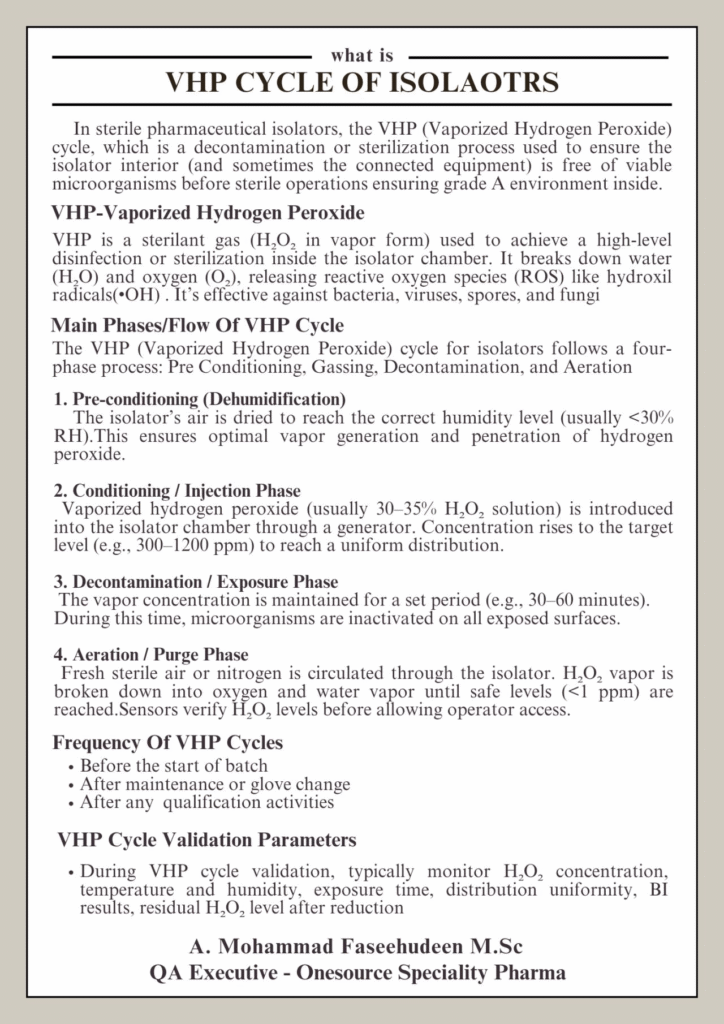

What is the VHP Cycle?

The VHP cycle is an advanced sterilization and decontamination process used inside pharmaceutical isolators. By using hydrogen peroxide in vapor form (H₂O₂), this process destroys a wide array of microorganisms—bacteria, spores, viruses, and fungi—ensuring a grade A sterile interior for high-stakes manufacturing tasks.

Unlike traditional chemical or heat sterilization, VHP is highly effective, leaves no toxic residues, and meets stringent GMP and regulatory requirements.

How Does VHP Sterilization Work?

Hydrogen peroxide vapor acts as a sterilant gas. When vaporized, it releases potent reactive oxygen species (ROS), such as hydroxyl radicals (- OH), which quickly oxidize and inactivate microbes. This deep-penetrating sterilization is effective even in complex isolator geometries.

Four Critical Phases of the VHP Cycle

1. Pre-conditioning (Dehumidification)

The cycle starts by lowering the isolator’s humidity below 30% relative humidity. Low moisture optimizes vapor generation and ensures vapor can reach all surfaces, even tiny crevices. This step is crucial for complete coverage.

2. Conditioning / Injection Phase

Vaporized hydrogen peroxide, typically a 30–35% H₂O₂ solution, is introduced to the isolator through a special generator. Vapor concentration is raised and distributed evenly (target: 300–1200 ppm), critical for uniform kill rates and compliance documentation.

3. Decontamination / Exposure Phase

Here, the vapor is held at target concentration for a controlled duration (commonly 30–60 minutes). This ensures comprehensive inactivation of viable microorganisms on exposed surfaces—directly impacting GMP compliance and product safety.

4. Aeration / Purge Phase

Fresh sterile air or nitrogen is circulated after decontamination. The H₂O₂ vapor breaks down into water and oxygen, reducing residual levels to below 1 ppm—safe for operator entry. Sensors continuously monitor and verify these levels, preventing accidental exposure.

When to Run the VHP Cycle?

- Before starting a new manufacturing batch

- After maintenance, validation, or glove changes

- Following any event that could jeopardize isolator sterility

- In routine qualification and requalification cycles

Validating the VHP Cycle: Key Parameters

For regulatory and QA audits, each VHP cycle must be validated. Typical monitoring parameters include:

- Initial and residual H₂O₂ concentration

- Isolator temperature and humidity data

- Exposure time (ensuring microbial kill)

- Distribution uniformity (documented via chemical/biological indicators)

- Achieving target reduction in bioburden for GMP compliance

Why Isolator VHP Cycle Knowledge Pays Off

Staying informed on isolator VHP cycles is not just about compliance—it improves product safety, operational efficiency, and audit success rates. For recruitment agencies, QA executives, and pharma service providers, highlighting expertise in VHP cycle validation and GMP readiness is a proven way to stand out in a crowded field.

Iam a fresher